Fibre opening is key to good yarn spinning. Good, gentle opening ensures maximum retension of fibre strength by minimizing fibre rupture, reducing the level of neps, effective thrash removal and minimal amounts of micro dust and lint. It is obvious that well cleaned and opened fibre is a prerequisite to high quality carding and spinning.

However, the fact is that this is very difficult to achieve for a Spinning Mill since the fibre quality, fibre mix, product mix, etc. keep changing and the process has to be optimized to the new requirements. Even if the process is optimized, it is a challenge to maintain the consistency of quality.

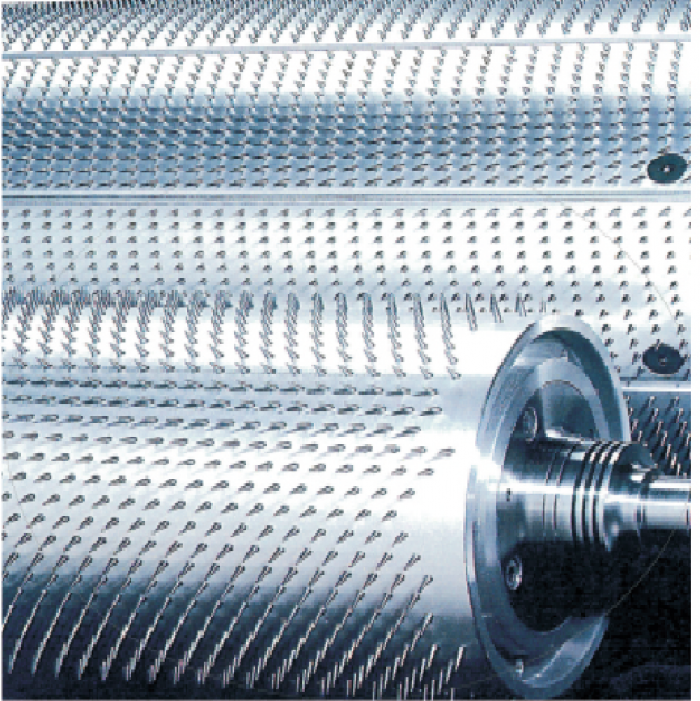

In this article, we discuss the issues related to this subject and how beater designs and the sequence of opening points influence fibre preparation. In modern blow rooms, four types of beaters are primarily used – disc beaters, peg beaters, pinned beaters and saw tooth beaters, each having it own function and suitability to certain requirements and conditions. As disc and peg beaters are used exclusively for beating and pre-opening of cotton fibres, we shall focus on pinned and saw tooth beaters for detailed analysis.

It was not until the 1960’s that blowroom cleaning machines embraced metallic wire as an option to bladed, porcupine, vertical or pin beaters. Production limitations of traditional blowroom lines of around 300 kgs. / hr gave way to metallic wire wound cylinders enabling dramatic increases in production. This provided more intense opening and cleaning, however, not without quality concession. Metallic wire in many applications results in fiber damage and requires frequent maintenance.

Typical Indian mills producing fine ring spun yarn upto the 1980s used up to seven cleaning points in their blowroom lines and no metallic wire was used. Though in modern blowroom lines, it is claimed that less cleaning points are required which helps reduce fibre damage at high productions rates, what is actually done is that multiple cleaning points are provided in a single blow room beater or card. However, even if one or two cleaning points are actually reduced, use of metallic wire leads to aggressive opening and consequent fibre rupture, which affects ring spun fine yarns’ quality in particular.

It may be prudent to replace the wire wound rolls with pinned rolls to reduce fibre damage, particularly for fine count, ring spun applications. Most super high production lines are suited for Open End Spinning operations where quality demands are more forgiving. Ring spun yarns, on the other hand, are very sensitive to speeds, over beating, and aggressive cleaning. Machine makers are thus increasingly adopting the pin technologies to overcome some of the issues posed by aggressive metallic wire cleaning.

Engineering improvements, such as use of long lasting alloy steel pins, extruded alloy aluminium lags and special pin profiles, along with proven advanced methods of pin fixing (eg. NIF method adopted by Stewarts) that provides pin-point accuracy, have dramatically improved the performance of pinned beaters, which was never achieved in wooden products. Leading manufacturers of modern blowroom and carding machines have adopted pin rollers and pinned aluminum profiles as the primary recommended specification for the following reasons:

- Pins provide extended product life

- Pins are kind to fibres – reduced fibre rupture leading to yarn strength improvements.

- Pins provide fibre process flexibility

- Pinned products are easily repairable (cost savings)

- Extruded aluminum tubes and profiles are lightweight alternatives of most metallic wire applications with cast or steel base rollers

- High tech pin fixing methods provide pin point accuracy without grinding

- Pin designs provide improved fibre transfer /doffing

Choice of beaters and sequence of opening depends on the nature of fibre and the process requirements. Long staple cotton with low thrash would require lesser beating and more opening than short staple, thrashy cotton. Synthetic fibres require no beating and only gentle opening. Though not preferred, saw tooth wires can be used for opening polyester or nylon fibres. However, they can cause several problems if used for opening soft fibres like viscose since such fibres have a tendency to disintegrate under stress.

We now explain how the opening action of saw tooth wire is characteristically different from pins and how this affects fibre characteristics. In wire, the opening action is done by the knife-edges of the saw tooth, which tend to cut open the fibres. This causes fibre rupture and lint generation. This tends to increase the percentage of short fibres and the level of neps. The thrash contained in the fibre supply also tends to disintegrate into micro dust due to the saw tooth action.

In comparison, the pin has a smooth round surface and a spherical tip, which opens the fibres through a gentle untangling action. It is obvious that fibre rupture would be minimized as well as the consequent generation of micro dust and lint would also reduced considerably with the use of pins. The round profile of pins also has another significant advantage – that of higher performing life and more consistent quality of opening.

As time passes, the wear and tear of saw tooth of a lickerin roller leads to the knife-edge getting rounded thus reducing opening action significantly. Moreover, small cuts or crevices develop on the leading edge of the saw tooth, which tends to ‘catch’ the fibres and create neps. Usually, the edge of the saw tooth loses its sharpness in the first few months itself, thus causing a rapid deterioration in the fibre opening action. This is partially mitigated by grinding the roller so that the teeth regain their sharpness, but this lasts for much less duration before the deterioration occurs again.

Another significant effect of this loss of sharp edge is that the saw tooth begins to push fibres rather than open and carry them forward. This obviously results in an increase in fibre droppage, leading to a loss of rich fibre and lowering of fibre yield. Any Mill can easily establish this phenomenon if they calculate the fibre yield of a single Card before and immediately after change of lickerin wire. One should not be surprised to find a difference of 2% or even more in the fibre yield!

However, since the pin has a rounded tip, it retains its opening ability much longer. Additionally, the wear all around the tip causes a new tip to be formed as the old one is eroded, though the pin length gets slightly reduced. This results in several significant benefits – increase in life of pins, more consistent opening action thus ensuring a consistent sliver quality and a higher fibre yield as compared to saw tooth wires.

The benefits of pinned beaters in the blow room are demonstrated by two studies we have conducted in Indian Mills. The results of the study, comparing the performance of saw tooth and pinned beaters under the same process conditions, are presented in the EXHIBITS 3 & 4. The first study was done in an Open End Spinning Mill having a Lakshmi-Rieter Blow Room line by running the same cotton fibre alternatively with a saw tooth beater and a pinned beater in the ERM position. Basant Wire, jointly with D.K.T.E. Society, Ichalkaranji, conducted the study. The second study was conducted in a Ring Spinning line having a Trutzschler Blow Room where in the TFV beater, a high-density pinned TFV beater was tried in place of a low density one to study the improvement in opening dyed synthetic fibres.

It can be concluded from EXHIBIT 1 that replacement of saw tooth ERM beater by a pinned one caused a significant improvement in performance. This improvement was observed even though the fibres had been subjected to saw tooth opening in the earlier stages before reaching the ERM. The most significant benefits were reduction in fibre rupture, reduction in neps, reduction in short fibre percentage, which reflected in improvement of yarn quality. In the yarn, improvement in LEA count and CSP, reduction of thick/thin places and in hairiness were observed. The benefits were more significant in the coarser yarns. It must be noted that the benefits can be further optimized by using pinned beaters in the earlier stages, by changing pin densities, beater speeds, etc. to suit the product range. This is discussed later in this article.

A close study of EXHIBIT 2 would reveal a 15% overall improvement in the opening efficiency when using the higher density pinned beater. This was done to address the problem of insufficient opening faced by the Mill, which did not have the space to install a new beater.

The above two studies highlight one major factor regarding fibre opening – that fibre preparation process and beaters need to be designed specific to the requirements and fibre characteristics. Key process conditions and requirements influencing selection of beater designs are –

- Type of fibre – as mentioned earlier, synthetic fibres need to be opened using a different process than cotton. Even the type of cotton or synthetic fibres has a bearing on the preparatory process.

- Cleaning – the percentage of thrash in cotton will determine how many opening points and what intensity of beating are required.

- Fibre rupture – there is a trade-off between better cleaning and fibre rupture so a delicate balancing act is required. What achieves better cleaning can also cause higher fibre rupture, if not carefully managed.

- Micro dust – Saw tooth beaters are generally easier to use but in case of thrash content being high, micro dust generation can be a problem with such beaters.

- Lint – low micronaire cotton tends to generate more lint with saw tooth wires.

- Neps – generally, neps level tends to increase with the increase in short fibre percentage, though this is not always the case. The preparatory system design has to consider the causes of neps to minimize them.

- Production rate – what works in a low production line may not do so for high production rate. Consistency of quality becomes a primary factor when designing a high production preparatory line.

- Desired quality of yarn- preparatory requirements differ for fine counts and coarse counts, with fibre rupture being a much more significant quality factor in case of higher counts as is the levels of lint and neps.

- Maintenance cost – This becomes a very sensitive issue in high production lines as breakdowns, repairs and reconditioning mean loss of production, increase in operating expenses and inconsistent quality.

- Fibre yield – sometimes there is a trade-off between higher fibre yield and a better opened and cleaned fibre – which one is more important depends on the quality of yarn produced.

It is beyond the scope of this article to discuss what specific design and process changes are required in the fibre preparatory to address each of the factors. This, in itself, is a subject of constant research by machinery manufacturers and accessories producers. However, we list the principal design factors that are used to influence a beater’s performance. These factors are common to both saw tooth and pinned beaters.

Design factors in beaters –

- Diameter – increase in diameter helps reduce the r.p.m. of the beater and also helps increase production. This is an option open only to machine manufacturers, though.

- Opening points density; projection and angle of points; and tip profile – they influence intensity of opening and cleaning, operating life, reduction in neps and fibre rupture

In conclusion, we can state that proper design of the preparatory line and regular condition monitoring of the beaters is key to consistent yarn quality and good fibre yield.

With all the latest developments in pins and pin product technology it is not inconceivable that we may well see a wider usage of these products in other key blowroom and carding areas, especially where current product life cycles are of concern.

Increased production rates in carding may well necessitate the adoption of pins in key areas eg. fixed carding segments, revolving flats and cylinders, particularly as card cylinders are reduced in size for speed increases. This could well pave the way for a revolutionary alternative to current technologies. High-speed aluminum tube carding rollers and pinned segments may well prove to be a feasible approach to higher carding rates and improved product life cycles.

Cost of pinned openers has always been a consideration. However, with advanced drilling and pin insertion methods, the cost differential between saw tooth and pinned rollers would be significantly reduced. In any case, even at current costs, pinned rollers justify the higher investment in terms of the extra life as well as the higher quality and production efficiencies they achieve.

About the authors:

Mr. Brian Leach is a graduate with distinction from Bolton Institute of Textile Technology, England with six decades of experience in manufacture and sales of textile machinery and an expert in design and production of pinned rollers. He is the promoter and President of Stewarts of America Inc., a world leader in manufacture of pinned products.

Mr. Kishore Khaitan is an MBA with distinction from Boston University, U.S.A. and has three decades of experience in production of pins and pinned textile machine accessories. He has extensive experience and expertise in design of pins, pinned rollers and their application in textile machinery. He is the promoter and Managing Director of Basant Wire Industries (P) Ltd., a market leader in India and manufacturer cum exporter of pins and pinned products.

EXHIBIT-1 |

|||||

| Overall Performance Upto Carding | |||||

| Type Of Beater at ERM | Saw Tooth | Pinned | |||

| S.N | |||||

| 1 | % Drop in UQL from bale mixing to Card Sliver | 5.8 | 3.1 | ||

| 2 | % Increase in Short Fibres from bale Mixing to Card Sliver | 27 | 9 | ||

| 3 | % Increase in Neps from bale Mixing to Card Sliver | 145 | 121 | ||

| Performance in Open End Spinning | |||||

| Yarn Strength | |||||

| 1 | CV% Lea Count | 5.6 | 3.1 | ||

| 2 | CV% Lea Strength | 8.3 | 6.3 | ||

| 3 | CV% CSP | 5.3 | 4.7 | ||

| Yarn Evenness | 7s Count | 10s Count | |||

| 1 | U% | 12.68 | 12.15 | 12.18 | 12.1 |

| 2 | C.V% (1M) | 6.42 | 5.43 | 6.22 | 5.82 |

| 3 | Thin | 14 | 10 | 7 | 7 |

| 4 | Thick | 176 | 161 | 126 | 110 |

| 5 | Neps | 28 | 34 | 37 | 34 |

| 6 | Hairiness | 6.35 | 6.11 | 5.38 | 5.23 |

EXHIBIT-2 |

|||||||||

| COMPARATIVE Study of New Fine TFV 1600 Beater | |||||||||

| S.N | |||||||||

| Make | Existing Beater ( Trumac) TFV 1600 | New Beater ( Basant ) Fine TFV 1600 | |||||||

| 1 | No of Pins | 7500 | 19000 | ||||||

| 2 | P.P.S.I. | 4 | 10 | ||||||

| 3 | Pins Height | 12.5 mm | 6.5 mm | ||||||

| 4 |

Gauge |

||||||||

| a) | Feed roll to Beater | 3 mm | 3 mm | ||||||

| b) | Beater to Stripping Plate | 1 mm | 1 mm | ||||||

Yarn Results |

|||||||||

| Lot No | 70171 | 70163 | 70173 | 70107 | 70175 | 70038 | 70174 | ||

| Shade No | 618/1103 | 618/1016 | 618/1016 | 615/1016 | 615/1016 | 618/3472 | 618/3472 | ||

| Beater | Trumac | Basant | Trumac | Basant | Trumac | Basant | Trumac | Basant | |

| Yarn U% | 8.32 | 8.41 | 8.18 | 9.00 | 8.38 | 10.59 | 8.99 | 8.45 | |

| Thin/Km | 0.00 | 0.00 | 1.30 | 0.30 | 0.00 | 0.00 | 1.00 | 0.00 | |

| Thick/Km | 7.50 | 6.00 | 20.50 | 13.30 | 14.00 | 11.00 | 17.00 | 8.40 | |

| Neps/Km | 28.50 | 27.50 | 65.30 | 50.70 | 48.00 | 35.80 | 44.75 | 26.90 | |

| Total Imperf./Km | 36.00 | 33.50 | 87.10 | 64.30 | 62.00 | 46.80 | 62.75 | 35.30 | |

| AutoConer Cuts/100 Km | 81.00 | 67.00 | 119.22 | 107.00 | 81.40 | 82.00 | 67.43 | 52.37 | |