Pinned Lickerins reduce fibre loss and provide consistant fiber sliver quality

For Rieter, Trutzschler, Lakshmi, Crosrol, Marzoli and other lines.

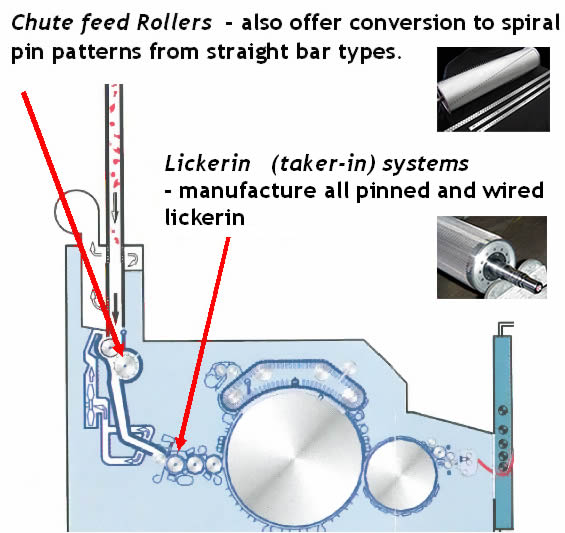

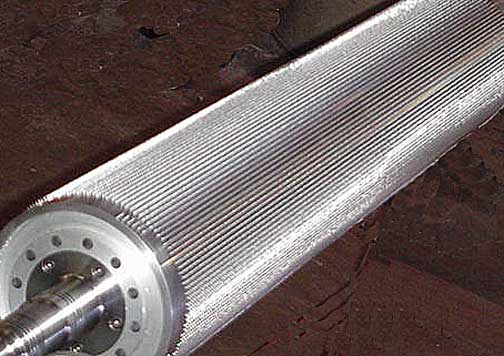

High-production cards now require advanced technology to reduce fibre rupture and achieve high nep removal efficiency while maintaining high production. Pinned spiral chute feed and licker-in rollers help achieve these objectives with added benefits of long life, consistent quality and fibre savings.

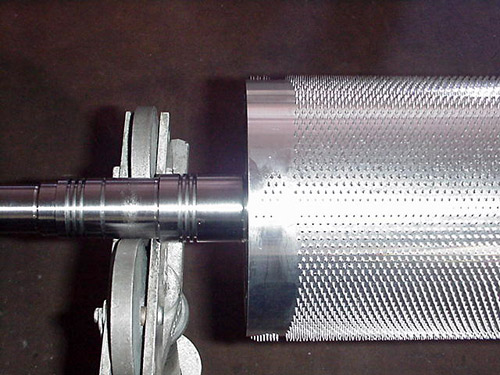

Pinned Lickerin Rollers

Pinned lickerins have several advantages over saw-tooth lickerins:

- About 6-8 years life compared to 6 months of saw tooth wire.

- Reduced fibre loss due to long effective life of pin tips

- Improved and consistent quality due to reduced fibre rupture and better opening.

Repinning of rollers and spiked bars using high quality pins, with accurate pin height, no damage to holes, no pins falling out problem.