Mills pay a lot of attention to the quality of cotton during the purchase but many are not aware of how much damage is happening to fibers before spinning. Ideally, one would like the properties of original fibers to be maintained in processed fibers.

In the case of synthetic fibers, it is even more critical to avoid rupture – these are more sensitive and subject to damage easily. Rupture in synthetic fibers not only causes serious quality issues but also plays havoc with the production process leading to high variability and frequent stoppages in production. The use of chemical sprays, dyes, and powders also adds to complications in synthetic fibers.

Fiber rupture can cost heavily in terms of :

● Increasing short fiber content

● Increasing hairiness of yarns

● Generating micro-dust

● Weakening fibers hence reducing CSP

● Increasing spindle breaks and winder cuts

● Increasing process waste and reducing yarn realization

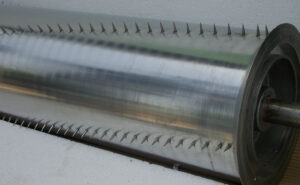

The above effects lead to a significant loss of production, efficiency, fiber yield, and yarn quality. So, everyone should be interested in reducing rupture. Adopting gentle spinning is the solution to minimize these problems. Wire causes harsh opening due to the knife-edged saw tooth wires whereas Pins do gentle opening due to the smooth rounded tips which last very long too. In addition to minimal rupture, Gentle Opening ensures better cleaning of trash, removal of powders, better opening, and more consistency ( due to long life) in the preparatory process. Many of our clients have also been able to reduce comber noil % upon using Pinned Rollers in Blowroom and Cards.

We, at BASANT FIBERTEK, specialize in gentle fiber opening solutions using the right design of Pinned Beaters, Pinned Lickerins, and the right machine settings to achieve optimal results in terms of production, quality, and yarn realization. We have successfully made improvements for many of our customers and we would be happy to do it for you also. We can study your process parameters and offer solutions to meet your improvement targets. Merely replacing saw tooth rollers with pinned type is not enough, one has to also optimize the settings for best results from pinned beaters. Same settings as wire rollers will not give many benefits since the action of wire on fibers is a cutting action under pressure ( close settings) whereas the action of pins is a gentle untangling action without pressure ( open settings). Due to the significant reduction in waste, savings generated can provide a payback in 6-9 months ( life of pin rollers is 4-10 years, depending on operating conditions) for the investment on retrofitting wire rollers with pinned ones.

SAVE FIBERS, SAVE PRODUCTION LOSS, SAVE PROCESS WASTE. Adopt sustainable Spinning through Gentle Spinning!